Benzotriazole (BTA) and Tolyltriazole (TTA) (including their sodium salt forms) are among the most common anti-corrosion agents used in copper pipes and for other industrial uses. BTA and TTA are broadly used in the oil & gas industry, power generation, chemical production, heavy machinery, and many other scenarios. The global consumption of BTA and TTA is estimated to be around 30,000 tons per year and the domestic consumption is estimated to be around 15,000 tons per year in the U.S.

Technological Readiness

Vulpes has developed its own supply chain and manufacturing processes for BTA and TTA. Traditionally, the chemical synthesis processes require high temperature (around 200 °C) and high pressure (50-100 kg/cm2). The traditional processes hence require specialty equipment and significant capital investment.

Vulpes’s processes are simple, continuous processes under atmospheric conditions, requiring no high temperature, no high pressure, and no specialty equipment. The processes are simple and cost-competitive against global suppliers. Vulpes is also able to provide its own starting materials. The processes hence allow for quick release to the market both in the U.S. market and to the global market.

Proprietary Products

In addition to standard BTA/TTA, Vulpes has also developed a number of proprietary, oil-soluble derivatives. The common oil-soluble derivatives use Formaldehyde in the manufacturing process and can release Formaldehyde throughout the life of the product. Vulpes has developed a number of other structures that demonstrate the same performance, but do not use or release Formaldehyde, both for a greener manufacturing process and for better compliance with EU and other regions.

Product Readiness

Vulpes has scaled up the manufacturing processes. Vulpes can provide samples immediately. Vulpes will launch full-scale production of BTA/TTA in 2024, from its U.S. based manufacturing facility. Vulpes offers BTA/TTA in powder, granular, and flake forms.

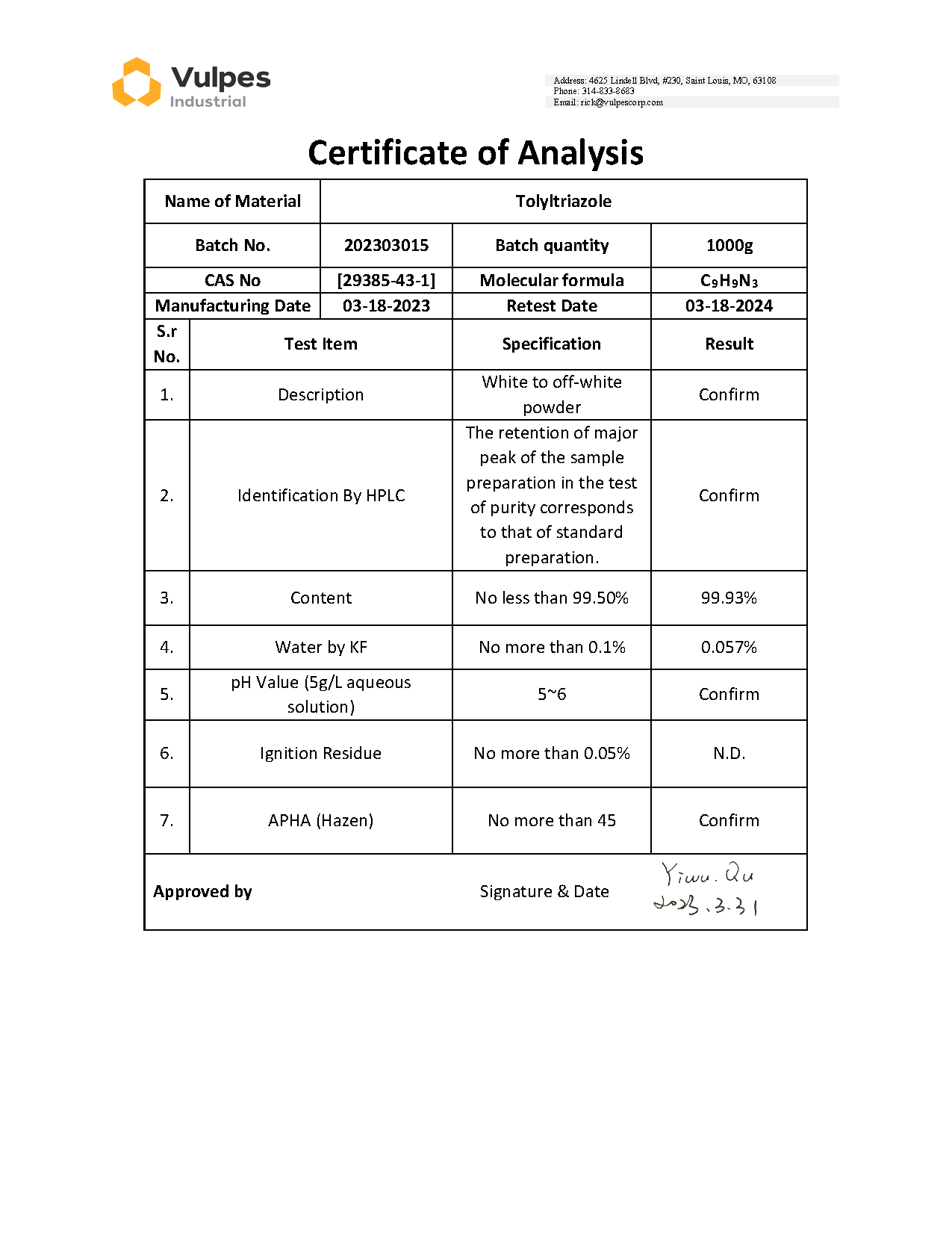

Sample COA